Polyurethane Foam Solutions \

Polyurethane Foam Testing

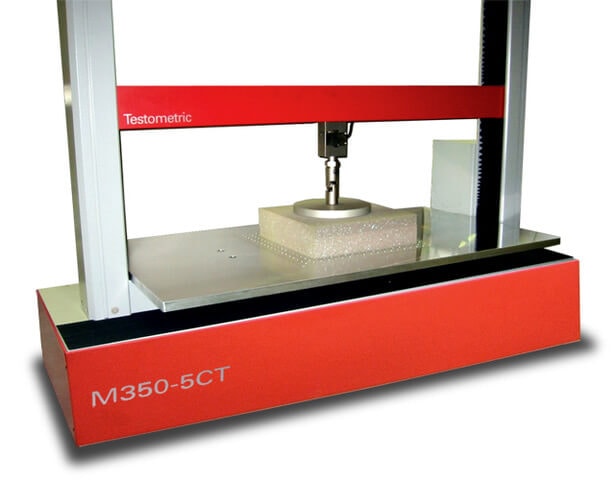

Hardness testing utilising Testometric M500CT Universal testing machines running Integral PC system running winTest™ analysis universal testing software is extensively carried out for prototype and production foam moulding.

CNC Milling and Moulding of all PU Foams

Rapid Response Quotes

Bespoke Hardness Reports

Prototype to Production

Where required 3rd party foam testing can be carried out typically for:

- Surface Spread of flame

- Flammability to various standards

- Toxic fumes

- Smoke density

- Cone Calorimeter Vertical burns test

- Constant load pounding testing

- Fire Risk Evaluation

Automotive seating HR flexible foam systems have been extensively tested to JLR standards.