Polyurethane Foam Solutions \

Prototype Foam Milling

We specialise in providing OEM Manufacturers and Tier 1 suppliers from a range of sectors with the tools and services they need to take a seating idea from design to prototype and beyond.

CNC Milling and Moulding of all PU Foams

Rapid Response Quotes

Bespoke Hardness Reports

Prototype to Production

CNC Foam Cutting

Direct from CAD accurate and rapid CNC Machining of soft and rigid polyurethane foams, expanded polypropylene (EPP), tooling boards, resins and polystyrene. Having the in-house ability to mould bespoke foam blocks to given hardness, density and flame retardancy allows for a flexible solution to CNC machine cut foam parts.

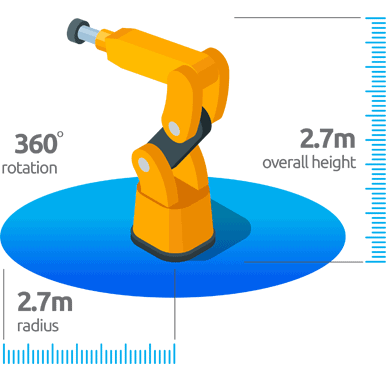

Our huge 7 Axis Robot Milling Cells with rotary tables plus Autodesk® PowerMill Robot software bring a high level of flexibility for fast accurate robot milling of foam seating and interior trim, sculptures, statues, exhibition, point of sale models and large-scale artwork, scaled-up models and patterns for advertising projects, film and television production and commercial events.

Our Robot machining cells are capable of producing the highest quality complex and unusual geometries including complex undercuts and 3D objects with a massive reach and a 3D workspace that include 10-station tool changers giving automatic flexible tooling selection for specific material removal.

7 Axis Robot CNC Milling Working Envelope