Polyurethane Foam Solutions \

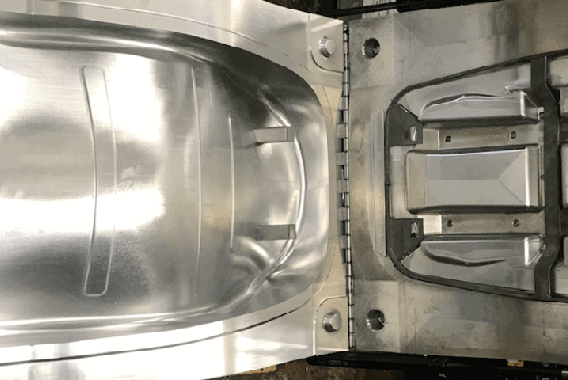

Foam Mould Tooling

Rojac specialises in the design and manufacture of polyurethane foam mould tooling, tooling can be a prototype of production and manufactured to form a range of materials. Polyurethane foam mould tooling is designed in house and manufactured by our experienced specially selected quality local toolmakers.

CNC Milling and Moulding of all PU Foams

Rapid Response Quotes

Bespoke Hardness Reports

Prototype to Production

Typical lead times from 3D CAD data to new finished foam mould tooling

| Tooling Type | Typicial Lead-Times from CAD |

|---|---|

| Rapid Prototype Tooling | 7-10 working days |

| Aluminium Billet Tooling | 4-5 weeks |

| GRP Resin Tooling | 5-6 weeks |

| Cast Aluminium Tooling | To be advised |